This idea came to me at some point in late 2012 when I was rooting around in my stuff and found these speaker drivers I had not used. Il Mundi my parents cat was milling about and the vision of mounting a speaker on his face came to me. Not really willing to sacrifice that sweet animal to a gruesome felicide by amateur taxidermy I set about to find an alternate solution.

The cubic restraints on the project came from a few directions. Fist and foremost of them is that I quite like the rigid motif and expressing something other with it. Then it is of course the fact that I had an idea about how to make stuff and source material for an object with flat surfaces. Finally I suspect that I had read this Calvin & Hobbes story earlier that day:

I then had a fairly clear view of what I wanted to do but since I am not adept at expressing myself it any graphical format I set about learning how to use sketchup witch is surprisingly easy. I mean it is not easy to do some things but still amazing what a novice can do with little previous knowledge of how to do 3D drawings.

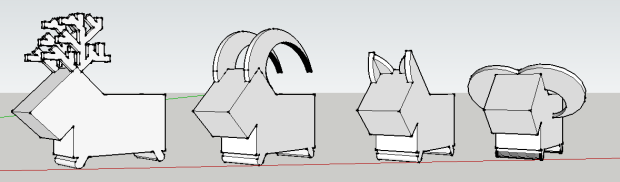

After about a week I had cobbled together the basic design for the body of the speaker as well as the basic distinctive features for a few designs. I used yet another cubic restraint or guiding principle on the design witch was to have the “animal” composed of golden ratios. This design principle was especially comfortable since sketchup has a convenient “snap to” feature when you reach the golden ratio on a square.

These were then the designs I had made:

These were then the designs I had made:

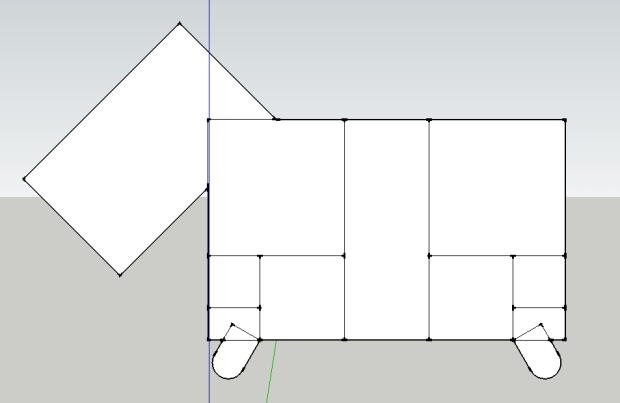

Now the nightmarish tedium started, taking every surface and flattening it out and drawing the interlocking teeth for them. Now I am sure that were I proficient at 3D drawing there would have been a quick and easy way to do this but as things were I had to do basically what amounted to drawing every tooth for hand. And as anyone who has any insight into how that might be done must see things did not always work out as they were meant to. Parts that were millimeters off would not snap together and then there were the parts with teeth and holes missing.

Now the nightmarish tedium started, taking every surface and flattening it out and drawing the interlocking teeth for them. Now I am sure that were I proficient at 3D drawing there would have been a quick and easy way to do this but as things were I had to do basically what amounted to drawing every tooth for hand. And as anyone who has any insight into how that might be done must see things did not always work out as they were meant to. Parts that were millimeters off would not snap together and then there were the parts with teeth and holes missing.

Despite initial problems already on my second prototype everything worked as it should, every tooth fit tightly into a groove and no gaps anywhere. When I say second prototype I am disregarding the two cuts that were made where the operator for the water jet robot cut along the inner contour of my lines and everything was loose and off by 0,7-0,14 millimeter (the approximate width of the water jet beam).

This is how the parts for the loudspeakers are made although production in Iceland seems to be a bit to expensive. I hope I can find another place that can make these things for me.

But where do we go from here?

Well you can always go and buy a pair of these things right here in my store Anthropomorphine on etsy.com